SCHUMACHER REMAINS ON EXPANSION COURSE

*Aachener Zeitung – local section, April 2014 – by Georg Pinzek

The long-established forwarding company is not only relying more and more on the logistics sector in the Aachener Kreuz industrial park

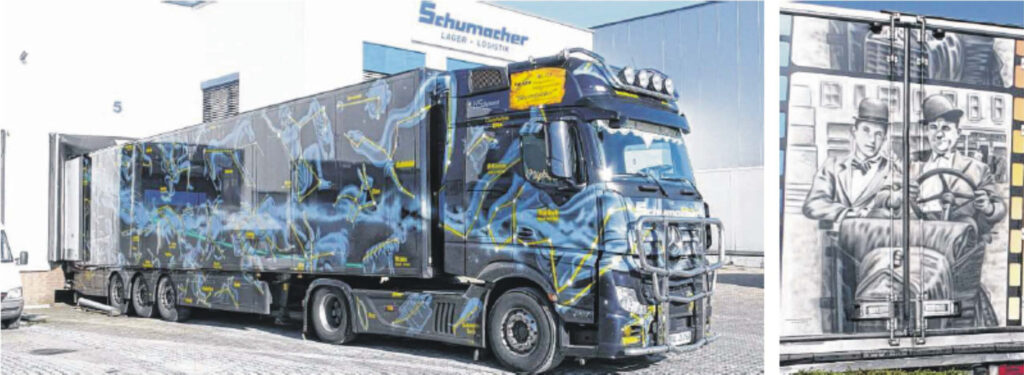

Würselen. There is something graceful about the way the forklift driver lifts and stows the pallets with goods on the shelves with his agile vehicle. Handling the steering wheel, pedals and levers looks so playful. It is these repetitive, fluid and fast movements that make you forget that tons of goods are moved here every day. With high precision and an inevitable tendency towards order. Every day and almost non-stop, this takes place behind the windowless warehouses and usually behind closed doors. Each pallet has an exact destination and that in a system of coordinates on the high shelves that is unmanageable for outsiders. This is where professionals are at work when it comes to effective goods storage and distribution. Now the Schumacher forwarding company at the Aachener Kreuz has given our newspaper a look behind the scenes – for a current occasion: The company is not only expanding at its location in Würselen. The traditional company from Aachen, the Inernationale Spedition Schumacher, has its headquarters in the Aachener Kreuz industrial park in Würselen at Sankt-Jobser-Strasse 51 (Tiefkühl Frischdienst Logistic e.K.) and at Monnetstrasse 8 (Spedition GmbH). The company has recently invested heavily in its logistics area and will continue to expand it. Because not only with its powerful truck fleet, the freight forwarding company is a parade horse of German medium-sized companies, but also as a logistician.

“Our company stands by the Aachen region.”

Managing Director Josef Schumacher

The forwarding company Josef Schumacher, Tiefkühl-Frischdienst-Logistic e.K., was founded in 1931 in Aachen by Josef Schumacher as a transport company. The transport business initially consisted of simple transports in the Aachen region. Managing director Josef Schumacher looks back with pride on the company’s history: “My grandfather personally picked up the milk from farmers with his truck. He had a dairy shop on Robensstrasse in Aachen.” But the first, more complex services were soon added to get the freight forwarding company on course. Areas such as transport, transshipment and storage, is especially known for its expertise in the area of fresh produce logistics Warehouse management (storage and warehousing) and co-packing are profiled. High quality chocolate and milk products as well as fruits are put together by hand by the employees in the warehouses for customer orders and packaged safely for transport. With its 320 employees, around 200 vehicles and around 45,000 square meters of managed logistics space, the Schumacher freight forwarder is well positioned. 150 new jobs were created in the past two years alone. In 2010, the company opened a large external warehouse in the district of Aachen called “Soers”. In the same year, the satellite warehouse in Richterich was extensively expanded and rebuilt for Lindt & Sprüngli and adapted to new standards. The warehouse in Würselen has been in operation with a further 12,000 storage spaces since September 2012. The construction of an additional 12,000 pallet spaces in Würselen will start these days. Well-known customers from the food industry and the retail trade illustrate the freight forwarder’s good reputation in the industry. Whether for example Lindt & Sprüngli or the two largest German discounters: Schumacher offers its extensive services for a whole range of other well-known companies as well as for the large ones in the German dairy industry.

Regardless of whether it’s apple or not-from-concentrate juice: “We specialize in the areas of refrigerated transport, warehouse logistics and the handling and dispatching of refrigerated goods,” says Schumacher. For the storage of temperature-dependent products in cold stores, their temperature depending on the requirements from 0 to

16 degrees can be regulated and digitally monitored, all prerequisites have been created. But that is not available for free. Such a warehouse, which looks inconspicuous from the outside, has it all: shelves and insulated external and partition walls cost three to four million euros, and another 1.5 million must be paid for the cooling technology. The demands on the food standard with strict requirements are justifiably high. In order

to reduce the electricity bill for around 1 million kilowatt hours of annual consumption, investments in solar systems will soon be due.

Schumacher can fall back on 200 refrigerated vehicles that are used in Europe-wide long-distance transport. , “complete evidence of the temperature control and documentation of the flow of goods, from production to the length of time in the warehouse to unloading at the recipient’s

premises. Of course, compliance with the hygiene regulations is extremely important; after all, we have a good reputation in the industry, “affirmed Schumacher.

600,000 pallets a year

Where once Vobis computers were screwed together and sold worldwide, Schumacher has rented space on a long-term basis, equipped it with modern shelving systems and stores there, for example, tons of vacuum-packed nuts. A total of 50,000 pallet spaces are available at four locations in the region. Instead of centralization, Josef Schumacher relies on a high degree of flexibility. This is undoubtedly necessary with a turnover of around 600,000 pallets a year!

By the way: The Schumacher transport company has remained loyal to the transport of milk to this day. The company supplies school milk for 800 schools in the region

to Kerpen, the Mönchengladbach area and the whole of the Eifel. Schumachers continues to rely on this city logistics despite its openness to the new developments that are vital to survival on the European market. “Our company stands by its roots and stands by the region. We just don’t forget where we come from, “says Schumacher.